Choosing a printing supplier in China can feel like a high-stakes decision, but it doesn’t have to be. This guide provides a proven, step-by-step framework used by professional publishers to eliminate risk. We’ll show you exactly how to identify and secure a reliable, high-quality book printing partner.

To vet a book printing company in China, a comprehensive due diligence checklist is essential.

This process involves verifying corporate credentials and export experience, assessing production capabilities like printing presses and binding equipment, and critically evaluating their quality control systems, including their color management standards and physical proofing policies.

Finally, scrutinize their communication skills and the expertise of their assigned project manager to ensure a smooth partnership.

Now that you have the basic framework, the real value is in the details. Read on to discover the specific questions that separate average suppliers from elite partners and learn to spot the critical “red flags” that most publishers miss.

Win the Battle Before It Begins

Before you even send your first inquiry, it’s crucial to adopt the right strategic mindset. Many publishers focus solely on unit price, a tactical error that often leads to problems with quality, communication, and delays.

Vetting isn’t just about filtering out bad suppliers; it’s about identifying the right type of partner for your specific needs.

The Chinese printing market isn’t flat; it has distinct, almost invisible tiers. Your goal is to navigate these tiers to find what we call the “Hidden Champions.”

- Tier 1: The Giants. These are massive, internationally recognized printers serving the world’s largest publishers. While their quality is top-notch, their minimum order quantities (MOQs) are often prohibitively high for small to mid-sized publishers, and their processes can be inflexible.

- Tier 3: The Domestic Players & Traders. This is the largest and most visible group, especially on sourcing platforms. They offer the lowest prices, but this is often a trap. Many primarily serve the domestic market and may not be aligned with international quality standards. Others are simply trading companies with no control over production, making quality a gamble.

- Tier 2: The Hidden Champions. This is your target. These are medium-sized, export-focused factories that view international publishers as their core business. They offer a powerful combination of high quality, competitive pricing, and flexible service. Finding them requires a more deliberate vetting process, which is precisely what this guide is for.

Shifting your focus from price to partnership is a strategic investment.

“The real cost is in the problems: the delays, the quality issues, the miscommunications. The purpose of a thorough vetting process is to find a partner who is not just a factory, but an extension of your own team.”

– Paul Adams, CEO of East West Manufacturing

This approach requires an upfront investment of time, but the returns are substantial. A systematic due diligence process isn’t a cost—it’s one of the highest-return investments you can make in your supply chain.

Craft a Specification Sheet That Commands Respect

Effective vetting begins with internal clarity. Before you approach any potential supplier, you must first create a comprehensive Project Specification Sheet, also known as a Request for Quotation (RFQ). Submitting a detailed, professional RFQ accomplishes three critical objectives:

- It enables fair comparisons. When every supplier is quoting on the exact same specifications, you can make a true “apples-to-apples” comparison. This prevents you from being lured by a low price that omits a key feature or uses substandard materials.

- It signals your professionalism. A thorough RFQ immediately distinguishes you from amateur buyers. Serious, high-quality suppliers are more likely to prioritize your project and provide a detailed response when they see you’ve done your homework.

- It forms the basis of your contract. This document will become a critical technical addendum to your manufacturing agreement. It serves as the definitive reference point for quality control and the legal basis for resolving any potential disputes.

Your specification sheet should be a detailed blueprint of your book. Leave no room for ambiguity. A strong RFQ must include the following details:

- Finished Specifications: Specify the final trim size (width and height), total page count, and binding style (e.g., saddle-stitched, perfect bound, smyth-sewn casebound).

- Paper Requirements: Detail the paper type (e.g., gloss art, matte art, uncoated offset) and weight (in gsm) for both the cover and the interior pages.

- Printing Colors: State whether the printing is CMYK, has Pantone (PMS) special colors (include the exact color codes), or is black and white.

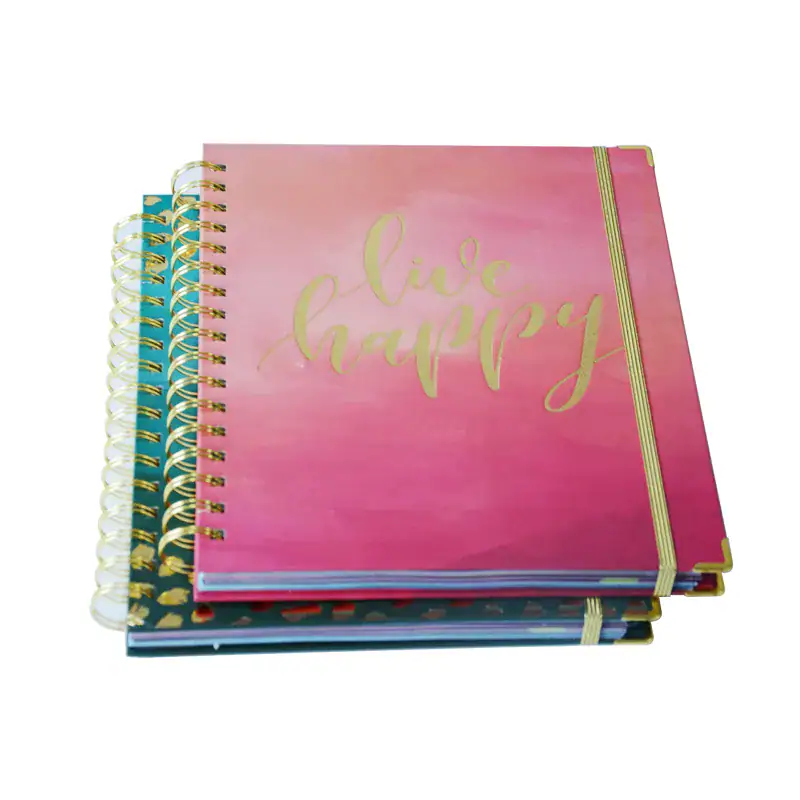

- Surface Finishing: List all post-press finishes, such as lamination (gloss or matte), foil stamping, spot UV, embossing, or debossing.

- Packing & Logistics: Provide instructions for individual book packaging (if any), units per carton, required shipping marks (唛头), and the destination port. Specify whether you require a quote for FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms.

- Tiered Pricing Request: Ask for quotes based on several quantities (e.g., 2,000, 3,000, and 5,000 copies) to understand the supplier’s price scaling.

A 10-Point Due Diligence Checklist to Expose Risks

With your detailed specification sheet in hand, you are now ready to engage potential suppliers. This 10-point checklist is your primary tool for due diligence. It’s structured to move from basic qualifications to the critical details of quality control and service, helping you systematically evaluate each potential partner.

Corporate Qualifications & Background Check

Think of this as your initial filter. These two points help you quickly weed out unqualified or risky suppliers.

- Business License & Export Experience: Ask for a copy of their business license to verify they are a legitimate, registered manufacturer. Critically, inquire about their export experience, specifically with your country. A supplier with a proven track record of shipping to your region will be familiar with customs requirements and logistics, reducing the risk of delays.

- Industry Certifications: Look for key certifications. ISO 9001 indicates a commitment to quality management systems, while FSC (Forest Stewardship Council) certification is essential if you require sustainably sourced paper.

Production Capabilities & Equipment

This level assesses the supplier’s physical capacity to produce your book to the required standard.

- Core Equipment List: Don’t just ask if they can print your book; ask what they will print it on. Request a list of their primary printing presses (e.g., Heidelberg, Komori) and binding equipment. Modern, well-maintained equipment is a strong indicator of a supplier’s commitment to quality.

- Binding & Finishing Capabilities: Confirm they have the in-house capability for your specific binding and finishing requirements. A factory that outsources complex processes adds another layer of risk and potential for miscommunication.

Quality Control & Process Management

This is the most critical part of the vetting process, applicable whether you’re printing books or need insights for sourcing promotional products with consistent quality.

It’s where you separate the factories that can produce a great one-off sample from those that can reliably deliver a great print run.

- Color Management System: Ask about their color management process. Do they adhere to international standards like G7 or Fogra? A professional printer will be able to clearly articulate how they ensure color accuracy from the digital proof to the final printed sheet.

- Proofing Process and Policy: How do they handle proofs? A physical press proof is non-negotiable for color-critical projects. Clarify the cost (a $100-$300 investment in a proof can prevent a $30,000 disaster) and the process for feedback and revisions.

- Internal Quality Control (QC) Process: Inquire about their QC checkpoints. Do they have documented procedures for incoming quality control (IQC) on materials like paper and ink, in-process quality control (IPQC) during printing, and final quality control (FQC) before shipping?

“Too many buyers assume their Chinese suppliers know and work to their quality standard. This is a dangerous assumption. You need to be explicit about your requirements and have a process in place to check them.”

– Renaud Anjoran, QualityInspection.org

After you receive a perfect sample, don’t stop there. Ask this crucial follow-up question: “This sample is excellent. Can you please describe the specific processes, equipment parameters, and inspection points you will use to ensure that the 4,582nd copy is 99% consistent with this one?”

A capable partner will welcome this question and detail their systems. A less reliable one will offer vague assurances.

Service & Communication

Finally, assess the human element. A great factory with poor communication is a recipe for frustration.

- Project Manager’s Expertise: You won’t be speaking to the machine operator. Who will be your day-to-day contact? Inquire about the background and English proficiency of the project manager who will be assigned to your account.

- Communication & Responsiveness: Gauge their communication from the very first interaction. Are their responses timely (within 24-48 hours), clear, and professional?

- Client Testimonials & Case Studies: Ask for references or examples of similar projects they have produced for clients in your country. A confident, experienced supplier will be happy to share their successes.

Ready to Print Your Book in China?

Navigating the complexities of overseas printing requires a trusted partner. Our team specializes in helping publishers like you achieve high-quality results with a seamless process. Let us handle the details so you can focus on creating.

The Art Beyond the Checklist: Reading the Signals

The checklist is your framework, but the true art of vetting lies in interpreting the responses and behaviors of a potential supplier. Your goal is to look beyond the written answers and understand what their communication style reveals about their operational reality.

Think of yourself as a “supplier psychologist,” watching for the subtle cues that signal either a reliable partner or a future headache.

Red Flags: Warning Signs to Heed

Certain behaviors should raise immediate concerns. These aren’t just minor issues; they often point to deeper problems in a company’s process or culture.

- Vague Answers: When you ask specific questions about their color management system or QC process and receive generic replies like, “Don’t worry, we are very experienced,” it’s a major red flag. A professional supplier will have documented processes and will be eager to share the details.

- Reluctance to Provide Samples: Any hesitation to produce a full, physical press proof is a deal-breaker. Excuses about cost or complexity often hide an inability to consistently achieve high quality.

- Poor Communication: Unresponsive sales reps, emails filled with errors, or a clear lack of understanding of your technical requirements are all signs of a communication breakdown waiting to happen.

- Unusually Low Prices: An offer that seems too good to be true usually is. An exceptionally low price often indicates that the supplier is cutting corners on materials, lacks a proper QC process, or will add hidden fees later.

Green Flags: Indicators of a Quality Partner

Conversely, positive signals can give you the confidence to move forward. These behaviors demonstrate professionalism, transparency, and a customer-centric approach.

- Proactive Questioning: A great supplier doesn’t just answer your questions; they ask their own. When they inquire about your file preparation, design intent, or specific finishing details, it shows they are engaged and committed to getting it right.

- Transparent Processes: They willingly share photos of their factory, provide details about their equipment, and can clearly articulate their production workflow from start to finish.

- They Assign a Dedicated Project Manager: The best suppliers will introduce you to the dedicated project manager who will handle your project, ensuring a single point of contact who understands your needs.

One of the most critical insights is to distinguish between the sales promise and the factory’s capability.

The friendly, English-speaking salesperson you communicate with is not the person running the printing press. Your vetting process must assess the reliability of the company’s internal communication system.

How is your detailed, English specification sheet translated into clear, actionable instructions for the production team? A strong supplier will have a robust system for this, often managed by a technically proficient project manager who bridges the gap between sales and production.

| Signal Type | What to Look For |

|---|---|

| Red Flags (Warning Signs) | Vague answers, reluctance to provide samples, poor communication, unusually low prices. |

| Green Flags (Positive Signs) | Proactive questions, transparent processes, dedicated project manager, clear communication. |

Turning Your Vetting Results into an Ironclad Contract

All your diligent vetting is for naught if you don’t formalize the agreements in a comprehensive manufacturing contract. In international trade, verbal promises and email exchanges are insufficient.

A detailed, legally binding contract is the only instrument that transforms the supplier’s commitments into enforceable obligations. This is the final and most critical step in risk management.

Your contract should be a direct reflection of your vetting process. Every key standard you verified and every process you confirmed must be explicitly written into the agreement. Don’t rely on standard templates; customize your contract to include these essential clauses:

- The Project Specification Sheet as an Addendum: Your detailed RFQ should be attached to and referenced in the contract as the definitive “Quality Standard.” Include photos of the approved physical proof, making it the “golden sample” against which the final production will be judged.

- A Clear Production Timeline with Milestones: Don’t accept a vague “delivery date.” The contract should specify deadlines for key milestones: final proof approval, start of production, completion of production, and the date the goods are ready for shipment. Include clauses for penalties in case of unapproved delays.

- Inspection and Acceptance Clauses: The contract must clearly state your right to conduct a third-party inspection before the final payment is made. Specify the quality standard to be used (e.g., AQL standards) and define the procedures for handling any identified defects (e.g., rework, replacement, or discount).

- Payment Terms Tied to Milestones: Structure the payment schedule to mitigate your financial risk. A typical structure is a deposit to start production (e.g., 30-50%), with the final balance due only after the goods have passed a final quality inspection and are ready for shipment.

- Intellectual Property (IP) Protection: Include a clause that explicitly states that you own all rights to your artwork and content, and that the supplier is prohibited from sharing, reproducing, or using your files for any other purpose.

Conclusion: Vetting Is Not a Cost, It’s Your Highest-Yielding Investment

That initial story of the $30,000 loss from a “perfect sample” wasn’t just a cautionary tale; it highlights a fundamental truth. A great sample proves a factory can produce quality, but only a great system can do it consistently.

The entire purpose of this comprehensive vetting process is to look past the sample and evaluate the system. You are moving from simply vetting a supplier to vetting their ability to reliably replicate quality at scale, and ultimately, vetting their suitability as a long-term partner.

By applying this 10-point checklist and the strategic insights within this guide, you transform vetting from a perceived cost into a high-return investment.

You systematically de-risk your project, protect your budget, and ensure your final product meets your standards. This empowers you to confidently leverage the cost advantages of printing in China and build a resilient supply chain, allowing you to focus on what you do best: publishing great books.

Ready to Start Your Printing Partnership?

You’ve created the vision. Now let our experts handle the printing with the quality your project deserves.

References & Notes

[1] ISO 9001: This refers to the international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

[2] G7 and Fogra: These are global standards and specifications for achieving visual similarity across all print processes. G7 (from Idealliance) is a proof-to-print process control method, while Fogra (a German research institute) provides standardized characterization data for various printing conditions. Both are crucial for predictable and consistent color reproduction.