Looking to choose a book printer in China without the associated risks? This actionable guide provides a proven 4-step vetting process and the 5 critical questions you must ask any potential supplier. Use this framework to verify quality, confirm safety compliance, and protect your investment from start to finish.

Choosing a reliable book printer in China involves a multi-step vetting process.

First, screen potential suppliers based on their portfolio and communication speed.

Then, ask critical questions to verify their safety certifications (like CPSIA/EN-71), technical expertise, quality control process, and factory legitimacy.

This guide delivers a complete framework based on our foundational guide to book printing in China to help you navigate the overseas printing process with confidence. Now, let’s dive in.

A 4-Step Funnel to Find Suppliers Worth Vetting

Quick Reference: Key Data for Printing in China

| Metric | Typical Data Point | Key Consideration & Notes |

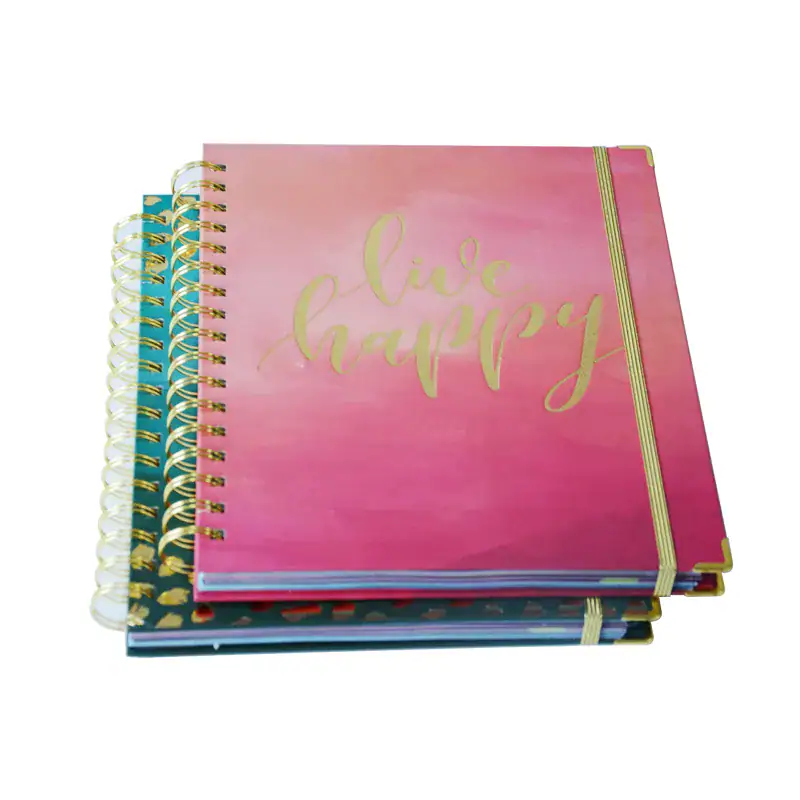

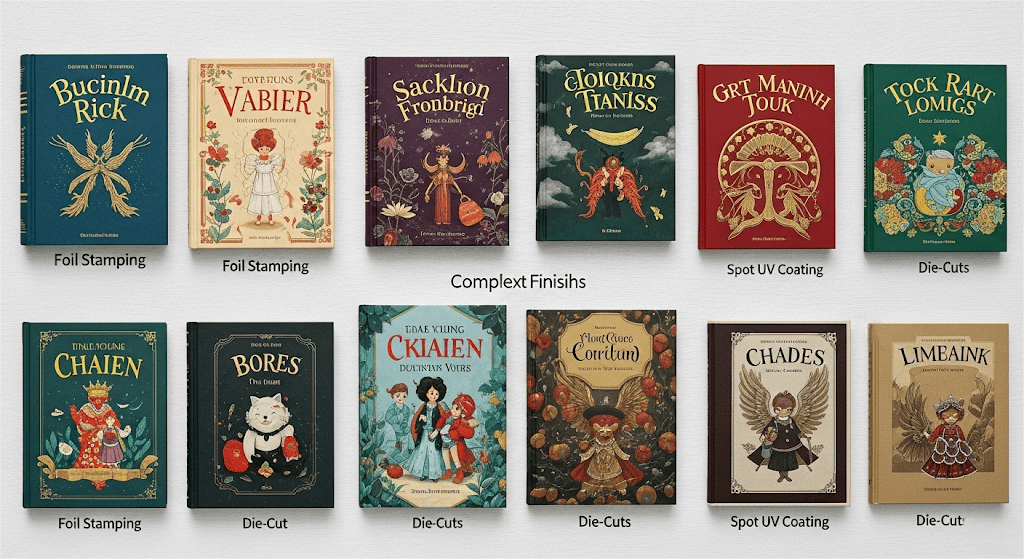

| Unit Production Cost | $2.80 – $6.00 | For a 32p hardcover. Special finishes like foil or UV add extra cost per unit. |

| One-Time Setup Fees | $200 – $1,000+ | Covers the essential physical sample (~$200) and any custom die-cut molds. |

| Minimum Order (MOQ) | 300 – 1,000 units | The minimum quantity required for cost-effective offset printing. |

| Total Timeline | 6 – 10 weeks | From final proof approval to delivery by sea. Crucial: Plan around the Chinese New Year holiday. |

| Shipping Cost (Sea) | $0.20 – $0.50 per book | This is the most economical method for bulk orders. |

Before you can ask the right questions, you need to find the right people to ask. This simple four-step process will help you filter through the noise and create a shortlist of promising candidates.

Step 1: Master Your Search to Avoid the Noise

To get relevant results, you need to use specific search terms. Instead of a broad search like “book printer China,” use detailed, long-tail keywords that match your project. For example:

- Children board book printing china FSC

- “Hardcover pop-up book manufacturer guangdong”

- “Custom journal printer with die-cut”

This approach will connect you with specialists, not generalists, saving you valuable time.

Step 2: The 60-Second Website Litmus Test

Once you land on a potential supplier’s website, you can quickly assess their suitability by checking three key elements:

Portfolio Review: Do they showcase numerous projects that are highly similar to yours?

If you’re creating a complex children’s book, look for evidence of their experience with children’s book printing, including pop-ups, special finishes, or board book construction. A strong portfolio is the best indicator of relevant experience.

Factory Authenticity: Look for photos and videos of their actual facility, equipment, and staff.

For instance, a UV printer is a key machine for high-quality book cover printing, so seeing one in their facility is a good indicator of their customization capabilities. Authentic visuals build trust, whereas generic stock images can be a red flag.

Visible Credentials: Reputable printers will proudly display their certifications.

Such as FSC (for sustainable paper sourcing), ISO (for quality management), or BSCI (for social compliance). The absence of these can indicate a lack of experience with international standards.

Step 3: Send a Standardized Request for Quote (RFQ)

To efficiently compare potential partners, send each one a consistent inquiry. Your initial email should ask for three specific things:

- A ballpark quote based on your specifications.

- Confirmation that they can provide a physical sample pack.

- Their Minimum Order Quantity (MOQ).

This standardized approach allows you to quickly evaluate and compare responses on an even playing field.

Step 4: Evaluate the Response: Your First Red Flag Test

How a company responds to your first inquiry is a powerful indicator of your future working relationship. We recommend applying the “24-Hour Response Rule.”

A professional, export-focused supplier should respond to your RFQ within 24 business hours. A slow, incomplete, or unprofessional reply at this early stage is a significant warning sign of potential communication challenges ahead.

5 Critical Questions to Ask Your Potential Printer

Once you have a shortlist, it’s time to start a deeper conversation. These five questions will help you assess a supplier’s true capabilities, professionalism, and reliability.

1、Can you provide valid safety certifications (e.g., CPSIA for the US) for a children’s book similar to mine?

Why This Is a Pass/Fail Question

For anyone creating a children’s book, this is the most important question you can ask. Safety is not a feature; it’s a legal and ethical requirement. Compliance with standards like CPSIA in the United States or EN-71 in Europe is a key part of children’s book printing safety,

ensuring the materials used are non-toxic and safe for young readers. A supplier’s ability to provide these documents demonstrates their experience with international markets and their commitment to quality.

Green Flag ✅: The Ideal Response: An experienced printer will respond with confidence. For example: “Yes, of course. We test every relevant batch. Here is a recent SGS test report for a board book we shipped to a client in California. We can walk you through the entire compliance process.”

Red Flag ❌: Evasive Answers to Watch For: Be cautious of vague replies like, “Don’t worry, our materials are safe,” or attempts to shift responsibility, such as, “The client is usually responsible for testing.” These are clear signs that they lack the necessary experience or are cutting corners on safety.

2、Could you share 2-3 recent examples of projects with similar complexity to mine?

Why This Matters for Customization

This question helps you verify proven capability, not just claims. Many printers will say they can “do everything,” but complex children’s books require specialized skills. You need a partner who has direct experience with your book’s specific features, whether it’s intricate die-cuts, pop-up elements, or special finishes.

As Jamey Stegmaier, founder of Stonemaier Games and an expert in complex overseas manufacturing, advises, “You must get a pre-production copy. There is no substitute for holding a physical sample in your hands to assess the component quality, color accuracy, and overall feel before authorizing mass production.”

Seeing their past work and getting a sample of your own is the only way to truly vet their quality, and it helps to understand the factors behind book proofing costs.

Green Flag ✅: The Ideal Response: A specialist will be eager to show off their relevant work. “Absolutely. Your pop-up book requires complex die-cutting and hand-assembly, much like this project we completed for [Brand Name]. Notice the clean cuts and registration. We can send you a physical sample.”

Red Flag ❌: Generic or Unrelated Answers: If a supplier responds with, “We can print any book,” or shows you a simple novel when you’re asking about a complex board book, it’s a sign they may not have the specific expertise you need.

3、Who will be my dedicated Project Manager, and what is their experience with clients in my region?

Why This Question Is Crucial

Your relationship is not with a factory building, but with the person managing your project. A dedicated, English-speaking project manager who understands your market is essential for a smooth process.

Clear communication prevents misunderstandings that can lead to costly mistakes and delays. Having a single, reliable point of contact ensures accountability and builds a strong working partnership.

Green Flag ✅: The Ideal Response: “Your project manager will be [Name]. She has eight years of experience working with US-based authors and publishers and is fluent in English. We would be happy to schedule a brief introductory call.”

Red Flag ❌: Evasive Answers to Watch For: A vague answer like, “Our sales team will help you,” is a major red flag. It often means no one has direct responsibility for your project, which can lead to confusion and a lack of accountability.

4、Can you walk me through your Quality Control process, from pre-press to final inspection?

Why This Builds Confidence

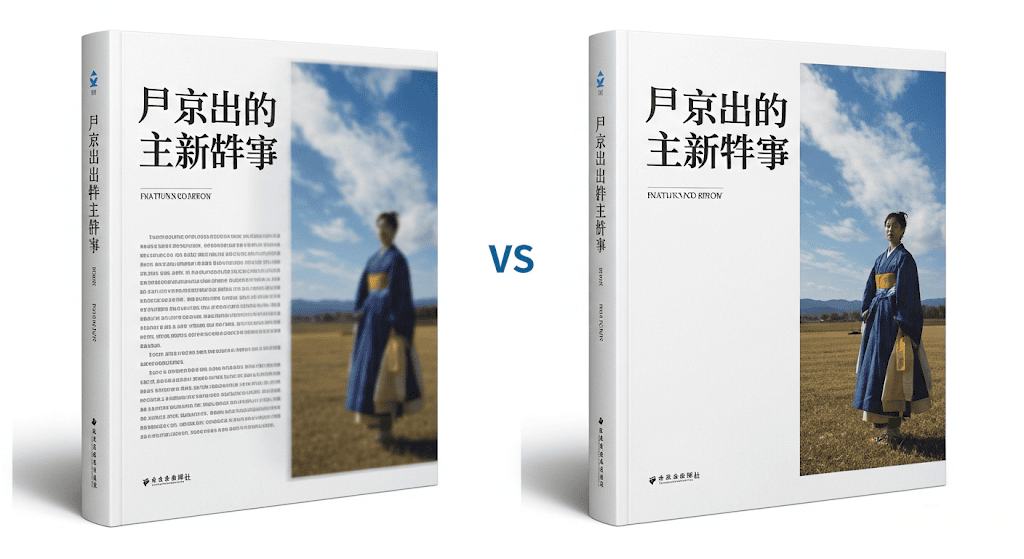

This question opens up the “black box” of production and gives you a sense of control. A reputable printer will have a clear, multi-stage quality control (QC) system and will be happy to explain it. Understanding their process for checking files, approving colors, and inspecting the final product ensures there are no surprises.

Green Flag ✅: The Ideal Response: “We have a 4-stage QC process. You’ll approve digital proofs, a physical dummy sample, the first printed sheets for color accuracy, and we’ll send a final production sample video before mass assembly. You will have approval at each key step.”

Red Flag ❌: Evasive Answers to Watch For: Beware of a non-specific answer like, “We have a QC department; we check everything at the end.” This suggests a lack of a systematic process and limited opportunities for you to provide input.

5、Are you a direct factory or an integrated service provider, and can you arrange a live video tour?

Why This Clarifies Their Business Model

The old advice was to only work with direct factories. Today, the landscape is more nuanced. Many top suppliers are “integrated service providers.” They may own a core printing facility but partner with specialized workshops for things like complex hand-assembly or custom finishes.

The key is transparency. A good partner, regardless of their model, will be honest about their process and how they control quality across their entire supply chain.

Green Flag ✅: The Ideal Response: “We are a direct factory for all printing and binding. For complex hand-assembly on pop-up books, we work with a dedicated partner facility that we manage and audit. We would be happy to schedule a live video call to walk you through our production floor.”

Red Flag ❌: Evasive Answers to Watch For: Any hesitation to answer this question directly or a refusal to offer a virtual tour is a significant concern. It may indicate they are a middleman with little control over the production process.

Real Stories, Real Lessons

Frameworks and questions are essential, but true wisdom often comes from real-world situations. Over the years, I’ve helped clients navigate this process, and I want to share a few stories that highlight why the advice above is so critical.

Case Study 1: The “Perfect” PDF vs. The Disastrous Proof

A client of mine, a meticulous graphic designer, was so confident in her “pixel-perfect” PDF files that she considered skipping the physical proofing stage to save about $200 and a week of time. I urged her to reconsider.

When the physical sample arrived, we saw that a key shade of sky blue on the cover had printed as a dull, purplish color. Worse, a pop-up mechanism inside was glued incorrectly and tore upon opening.

The Lesson: Screens can be deceiving, but a physical sample tells the truth. The cost of a sample is the best insurance you can buy for your project.

The Lesson: You are not just working with a company; you are working with a person. Ensure you have a stable, dedicated project manager who is accountable for your project from start to finish.

Frequently Asked Questions (FAQ)

What’s a realistic cost for printing 1000 children’s books in China?

While every project is different, for a standard 32-page, full-color hardcover children’s book, you can generally expect the unit cost to be in the range of $2.80 to $6.00, depending on the complexity, paper, and finishes. Remember that special features like pop-ups or die-cuts will add to this cost.

How long does printing and shipping really take?

You should plan for a total timeline of approximately 6 to 10 weeks from final proof approval. This breaks down into about 2-4 weeks for production and 4-6 weeks for sea freight to North America or Europe. It’s also critical to factor in potential delays. As logistics experts frequently advise, the Chinese New Year holiday significantly impacts supply chains, with most factories shutting down for at least two weeks.

What is an MOQ and why can’t I just print 50 copies?

MOQ stands for Minimum Order Quantity. For high-quality offset printing, the MOQ is typically 500 to 1,000 copies. This is because the initial setup costs for the printing press are significant. Spreading that setup cost over a larger number of books makes the per-unit price affordable. For very small quantities, the per-book cost would be prohibitively high.

What is the safest way to pay a Chinese supplier?

For samples, PayPal is often convenient. For bulk orders, a bank wire transfer (T/T) is standard. The safest payment structure is a 30-50% deposit to begin production, with the final balance paid only after you have approved photos of the finished, packed goods and are ready for them to ship.

Conclusion

Making the right choice for book printing in China is a significant decision, and the process involves more than just comparing price sheets.

As you’ve seen, there are nuances to everything from safety compliance to communication. A truly great printing partner is not one who promises a flawless process, but one who is transparent about risks and works with you to solve problems when they arise.

We believe an informed client is the best partner. The purpose of this guide is to empower you with the knowledge to ask the right initial questions. For a complete due diligence framework, we recommend our full 10-point supplier vetting checklist.

At Mainland Printing, our entire service process is built around understanding the needs of creators like you and providing the expertise and transparency necessary to protect your creative vision.