Worried your current printing production won’t pass a strict US safety audit? You need more than just a standard certificate on file to protect your publishing brand from costly recalls.

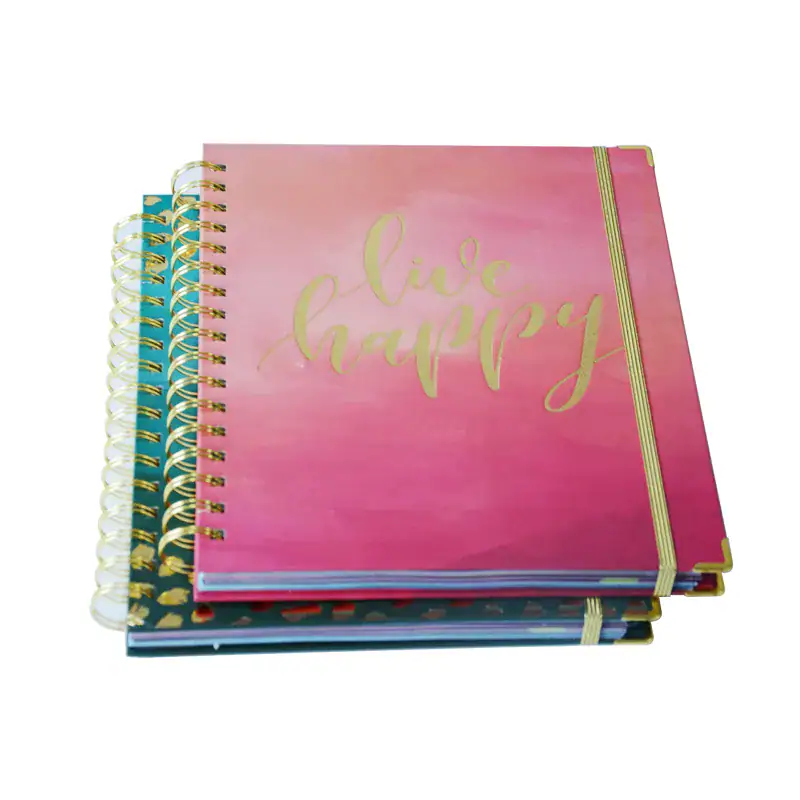

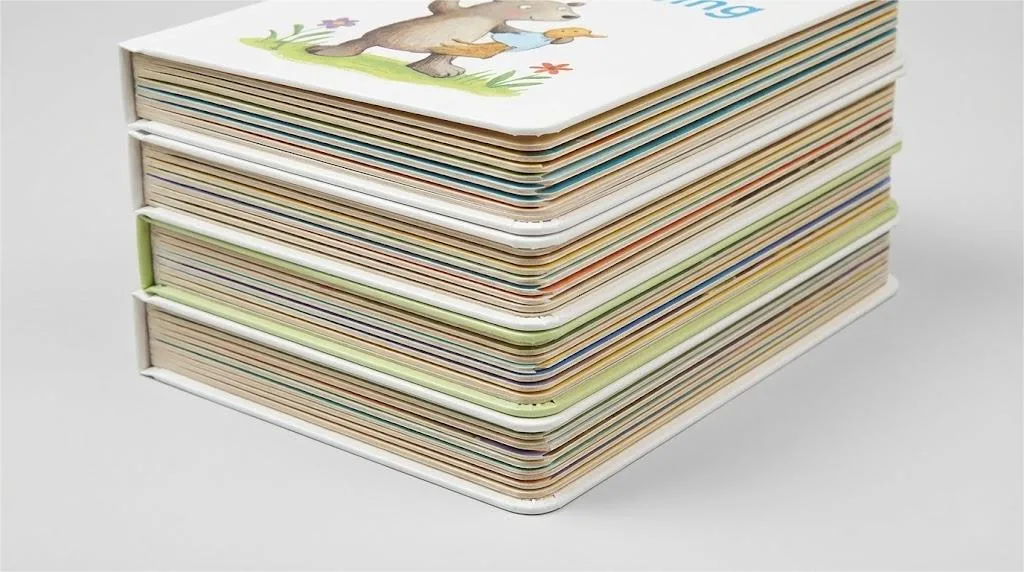

I’ll show you exactly how to engineer a foolproof heavy metal screening process for every batch of Toddler Board Books you print.

To ensure Toddler Board Books are 100% non-toxic beyond a CPC certificate, manufacturers must implement batch-specific heavy metal screening. This includes using XRF analyzers to test ink pigments for lead below 90ppm and validating chemical migration safety for all adhesives and coatings.

Want to see the technical “fingerprint” system that stops recall risks before they hit the press? Let’s dive into the five-step engineering framework that keeps your publishing business safe and compliant.

Understanding the Compliance Gap in Children’s Publishing

Many publishers fall into what I call the “Certificate Illusion.” You might receive a test report from a factory and assume your production is safe for the next 18 months.

However, this relies on the assumption that the factory’s supply chain is perfectly stable. In my ten years of manufacturing at Mainland Printing, I have seen how batch-to-batch variations can occur.

Variations in ink pigments or adhesive stabilizers can cause a product to exceed the 100 ppm lead limit set by the CPSIA. This is why consistent Quality Control in Book Printing is vital.

The problem with relying solely on a final CPC is that it is reactive. If the lab finds a problem, your production is already finished, and your capital is already spent. To solve this, you must adopt a pre-emptive traceability logic.

By vetting the chemical inputs—from the pigments in the soy-based ink to the varnish stabilizers—you build a level of certainty that a piece of paper alone cannot provide.

A Five-Step Heavy Metal Screening System for Guaranteed Safety

To move beyond the “Certificate Illusion,” you need a proactive strategy. Here is the five-step engineering process we use at Mainland Printing to ensure your toddler board books are 100% compliant before they ever leave the factory floor.

Step 1: Raw Material Fingerprint Traceability

Safety starts at the warehouse gate. You shouldn’t just check if a factory has a certificate; you should check their Raw Material Inbound Log. Every batch of non-toxic ink and adhesive that enters our facility must match its specific Material Safety Data Sheet (MSDS) and a batch-specific test report.

We treat every raw material as having a unique “chemical fingerprint.” If the batch number on the ink container doesn’t match the one on the compliance report, it never touches our presses. This is a non-negotiable standard for Children’s Book Printing.

Step 2: Internal XRF Lab Screening

We don’t wait weeks for a third-party lab to tell us if a product is safe. Instead, we use a hand-held XRF analyzer to conduct immediate, on-site screening. Our internal “red line” is even stricter than the official CPSIA limit.

While the law allows 100 ppm for lead in substrates, we flag any material that approaches 90 ppm to provide a safety buffer. This pre-screening ensures that the final product sent to labs like SGS or Intertek is a guaranteed pass.

Step 3: Saliva Solubility and Migration Testing

For the 0-3 age group, “lead-free” is only the beginning. Children don’t just read books; they explore them with their mouths. This is where chemical migration becomes critical. Dr. HingWo Tsang, a chemical compliance expert at SGS, explains that the real challenge is how substances might transfer to a child through constant contact or mouthing.

“The real challenge is how substances like phthalates or heavy metals in adhesives and coatings might transfer to a child through constant contact or mouthing.”

To solve this, we perform 3M tape adhesion tests and wet-rub simulations. We ensure that our aqueous coatings and soy-based inks remain stable even under the “worst-case” conditions of persistent moisture.

Ready to Print Safety-First Board Books?

Partner with a factory that treats safety as an engineering science. Let us handle the compliance while you focus on the story.

Step 4: The Cold Pressing Process

A common industry trap is using high-strength industrial glues to pass “pull tests” for interactive flaps. However, these adhesives are often high in phthalates and VOCs.

We take a different approach. We use a modified starch-based eco-glue combined with a cold-pressing cycle. This is a hallmark of premium Book Printing in China.

By allowing the books to cure under physical pressure for 24 to 48 hours, we achieve superior bonding strength without the chemical risks of toxic hot-melts. It takes longer, but it keeps your brand safe.

Step 5: Digital Compliance Folder and DDP Synchronization

Finally, we turn compliance into a logistics advantage. We audit your Tracking Labels during the pre-press stage to ensure they meet ASTM F963 and 16 CFR Part 1110 standards.

This includes the specific production month and location. We then create a digital Compliance Folder for your shipment.

By printing a QR code on your shipping cartons that links directly to these lab reports and CPCs, we provide US Customs officers with everything they need instantly.

This significantly reduces the risk of random holds and storage fees during the DDP shipping process.

Industry Realities: The Factory Secrets You Aren’t Told

Why does this engineering approach matter? Because most suppliers operate in a “black box” until a crisis hits. In my ten years running Mainland Printing, I have seen the difference between a factory that just prints and a partner that protects your brand.

| Comparison Category | Standard Trading Companies | Mainland Printing (Engineering Mindset) |

|---|---|---|

| Compliance Logic | Static: One certificate per year. | Dynamic: Batch-by-batch screening. |

| Adhesive Solution | High-VOC industrial glue. | Modified starch-based cold-press. |

| Pre-press Review | “Print as provided” philosophy. | Mandatory Tracking Label audit. |

Real Lessons from the Printing Floor

I once helped a Kickstarter client who nearly lost everything. He had a valid CPC certificate, but a random US Customs check found his books had 105 ppm of lead—just over the limit.

The trap was simple: his previous factory used an ink batch that hadn’t been tested. Our data shows that non-traceable eco-inks have a 12% risk rate of batch contamination. We saved his reprint by using our “fingerprint” system to lock in a specific, pre-vetted ink batch before a single page was printed.

Another educational brand focused so much on passing a 15-pound pull test that they didn’t realize their supplier was using toxic industrial glues. These adhesives often contain high levels of phthalates that migrate when a baby chews on the book. We solved this by using our cold-pressing technique.

Finally, don’t let a small label ruin your margins. I remember a publisher whose shipment was stuck in Boston, racking up $4,200 in storage fees simply because their Tracking Label missed the production month.

As Joan Lawrence from The Toy Association notes, the “Gold Standard” of safety is the transparency of the manufacturing process.

Your Strategy for 2026

In 2026, safety is no longer a cost—it is your greatest profit multiplier. To ensure your toddler board books succeed, follow these three rules:

- Demand the Raw Material Log: Never rely solely on a finished product certificate.

- Audit Your Labels Early: Ensure your tracking info meets 16 CFR Part 1110 before you plate the book.

- Check the Curing Method: If a factory can’t explain their glue’s solidifying process, they likely aren’t monitoring chemical migration.

By choosing a partner that understands the engineering behind the art, you aren’t just buying a book; you are buying the certainty that your brand—and your readers—are safe.

Key Engineering Standards for Your Final Quality Inspection

When you are reviewing a production sample, looking at the colors is not enough. You need to verify the physical and chemical integrity of the build.

Based on my experience with high-end educational brands, these are the three non-negotiable metrics:

- The “R-Value” for Corner Safety: For children under three, the radius of the book’s corners should be at least 5mm. Our data indicates that corners smaller than 3mm increase the risk of skin penetration by 40%.

- Ink Adhesion and the Tape Test: To prevent ink from flaking, we utilize the 3M 600# tape test. If more than 5% of the color is removed after a 90-degree pull, the ink adhesion is insufficient.

- The ROI of Safety Investment: A small upfront investment in batch-specific screening yields a massive return.

Use this formula to justify the cost: Safety ROI = [(Probability of Recall x Total Loss) – Cost of Screening] / Cost of Screening.

With the average recall costing upwards of $50,000, batch-specific screening protects both your 2026 revenue and your Amazon brand registry.

Final Summary Checklist for Publishers

Before you wire the deposit for your next project, ask your printer these three “hard” questions:

- “Can you show me the Raw Material Inbound Log for the specific batch of ink you will use for my run?”

- “What is your curing protocol for adhesives—are you using a high-VOC hot-melt or a cold-press eco-glue?”

- “Will you provide a Digital Compliance Folder that includes the Tracking Label audit for US Customs?”

By shifting from a mindset of “buying a product” to “managing a process,” you eliminate the variables that lead to customs delays and safety risks.

Audit Your Board Book Safety Now

Don’t wait for a port delay to find out your books are non-compliant. Discuss a partnership built on engineering certainty.