Before we dive into the detailed breakdown, here’s a quick overview of the challenge Galerie Éditions faced, the DFM solution we proposed, and the successful commercial outcome of this value-engineering project.

Project at a Glance

Client Opportunity

Galerie Éditions, a mid-sized Paris art publisher, needed to enhance the retail value of a new hardcover art book.

The Commercial Challenge

The desired deluxe slipcase was quoted 15% over the project’s strict, pre-set manufacturing budget, forcing the client to consider canceling it.

Our DFM Solution

Our technical team proactively analyzed the design and proposed a 2mm size adjustment, enabling a zero-waste layout on a standard paper sheet.

Final Business Result

The DFM tweak reduced the slipcase cost by 28%, allowing the publisher to add the premium finish with no increase to their total budget.

A Note on Client Confidentiality

At Mainland Printing, protecting our clients’ project details and intellectual property is a top priority. To uphold our commitment to confidentiality, the client name and book title in this case study have been changed. However, the project challenges, our solutions, and the final results described are based on a real-world engagement.

Project Brief

In the competitive art publishing market, a product’s “perceived value” is just as crucial as its content. A deluxe slipcase not only protects the book but also significantly enhances its shelf appeal and retail price point.

However, adding this finish often increases costs, forcing publishers to make a difficult choice between market competitiveness and budget control.

This case study analyzes how Mainland Printing, during a project in the fall of 2023, utilized proactive DFM (Design for Manufacturability) analysis to help a European art publisher successfully add a luxury slipcase to their hardcover catalog—all without exceeding the original total budget.

Client Background

Our client, “Galerie Éditions,” is a Paris-based, mid-sized publisher specializing in contemporary photography and fine art catalogs. Their core audience consists of collectors and art enthusiasts who have exceptionally high standards for print quality and design in Art Book Printing.

While preparing their major 2023 title, “The ‘Metamorphosis’ Photography Collection,” Galerie Éditions aimed for the book to be a benchmark publication for the season. They planned a high-spec hardcover format and strongly desired a custom slipcase to match the book’s artistic prestige.

The Problem

The challenge emerged during the initial quotation phase. Galerie Éditions had set a firm per-unit production cost ceiling for the project. When they requested a quote that included the custom slipcase, the total cost exceeded their budget by approximately 15%.

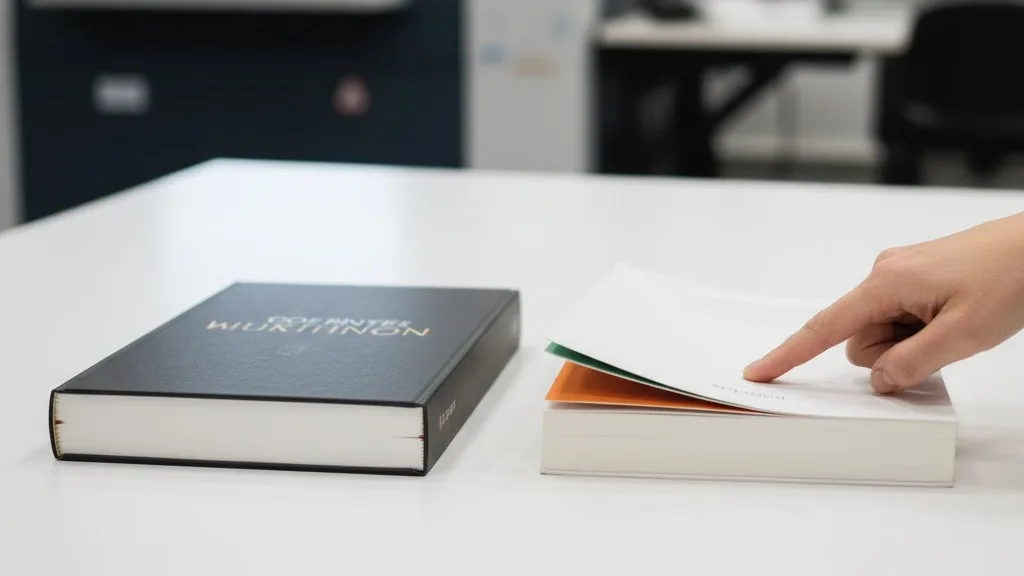

The slipcase was considered an “optional add-on.” Faced with this budget pressure, the client’s team was leaning toward abandoning the slipcase in favor of a more basic Hardcover Book Printing solution, using only shrink-wrap.

This was an unfortunate compromise, as it would have directly diminished the book’s market position and potential retail price. The client expressed their dilemma to us: they needed to elevate the product but could not breach their established cost threshold.

The Solution

Upon receiving feedback that the client might cancel the slipcase, our technical team did not simply accept the decision. Instead, we immediately initiated a DFM (Design for Manufacturability) review.

We believe a premier printing partner should not just passively fulfill orders but actively help clients achieve their business goals within their budget.

Our analysis focused on the slipcase, the component with the highest cost impact. The original design files showed that the slipcase’s flat, unfolded layout was not efficient on a standard press sheet, resulting in approximately 12% material waste.

Our solution was an extremely minor yet highly impactful engineering adjustment:

- DFM Analysis: Our prepress engineers analyzed the files and found that if the slipcase’s dimensions were adjusted by just 2mm, it could be nested perfectly on our standard 787mm x 1092mm parent sheet, achieving a “zero-waste” layout.

- Proactive Recommendation: We submitted a brief technical report to Galerie Éditions. We explained that this tiny dimensional tweak (e.g., from 242mm x 302mm to 240mm x 300mm) would be virtually imperceptible to the end-user and would not affect the book’s fit, but it would maximize the material yield.

- Cost Recalculation: Based on this adjustment, we recalculated the costs. This single change reduced the material and production cost for the slipcase unit by approximately 28%.

This expert recommendation brought the total project quote, including the slipcase, back down to the client’s original target budget. After reviewing our analysis, the Galerie Éditions team immediately approved the adjustment.

The Result

Through this proactive DFM intervention, Galerie Éditions successfully added the deluxe slipcase they had planned to cut, all without adding a single dollar to their budget.

- Product Upgrade Achieved: “The ‘Metamorphosis’ Photography Collection” was released in its intended “hardcover + slipcase” format, significantly boosting its product prestige and retail competitiveness.

- Budget Controlled: The client maintained strict control over their production costs, validating Mainland Printing’s value as their “growth partner.” We demonstrated that expert manufacturing knowledge can translate directly into a client’s profit margin.

- Strengthened Partnership: The client was impressed by our initiative to solve their problem and help them reduce book printing costs—a service that went far beyond the duties of a traditional supplier.

Project Key Parameters

| Parameter | Specification |

|---|---|

| Project Name | “The ‘Metamorphosis’ Photography Collection” |

| Client | Galerie Éditions (Paris) |

| Date | Q3 2023 |

| Quantity | 3,000 units |

| Format | Casebound Hardcover with Slipcase |

| Trim Size | 240mm x 300mm (Portrait) |

| Slipcase Specs | 3mm greyboard wrapped with 157gsm art paper, matte lamination |

| Core DFM Tweak | 2mm dimension adjustment to optimize layout on 787mm x 1092mm parent sheet. |

Our Takeaway

For publishers, printing costs should not be viewed as an unchangeable fixed expense. In practical production, there is significant room for optimization through expert knowledge.

This case study clearly shows that among the various book printing prices factors, manufacturing experience (DFM) is just as critical as paper and finishing.

A 2mm recommendation is backed by an engineer’s deep understanding of material properties, layout efficiency, and cost structures.

This is the core value of Mainland Printing as a “growth partner”: we are not just printers; we are an extension of our client’s product development and cost-control teams.

We are dedicated to finding the best ways to enhance book quality printing processes within their budgets, ensuring they get the maximum return on their investment.

Facing a Dilemma Between Budget and Quality?

If you are planning a new publishing project and want to maximize your product’s market value while maintaining strict budget control, we invite you to speak with our team of experts.

Let us review your specifications together to uncover the optimization opportunities that can translate directly into profit and competitiveness.

Ready to Start Your Printing Partnership?

You have the vision for a stunning art book. Let our technical experts and printing specialists bring it to life with the quality and value it deserves.

References & Notes

[1] Design for Manufacturability (DFM): This is an engineering practice focused on designing products in a way that optimizes for ease of manufacturing, reduced cost, and improved quality. In printing, this involves analyzing file layout, paper choice, and finishing processes to ensure maximum efficiency on press and in post-press.

[2] Standard Paper Sheet Size: The 787mm x 1092mm (31″ x 43″) sheet is a common “large format” or “parent sheet” size used in offset printing presses in Asia. Optimizing a layout to fit this standard sheet with minimal off-cuts is a primary goal of DFM and a key driver in reducing unit costs.