Are you developing a product with an intricate design, only to be told by suppliers that the process is “too complex” or “too high-risk”? Do you worry that the very special printing processes that give your product its soul could become a quality control nightmare in mass production? This is a common and valid challenge for ambitious creative projects.

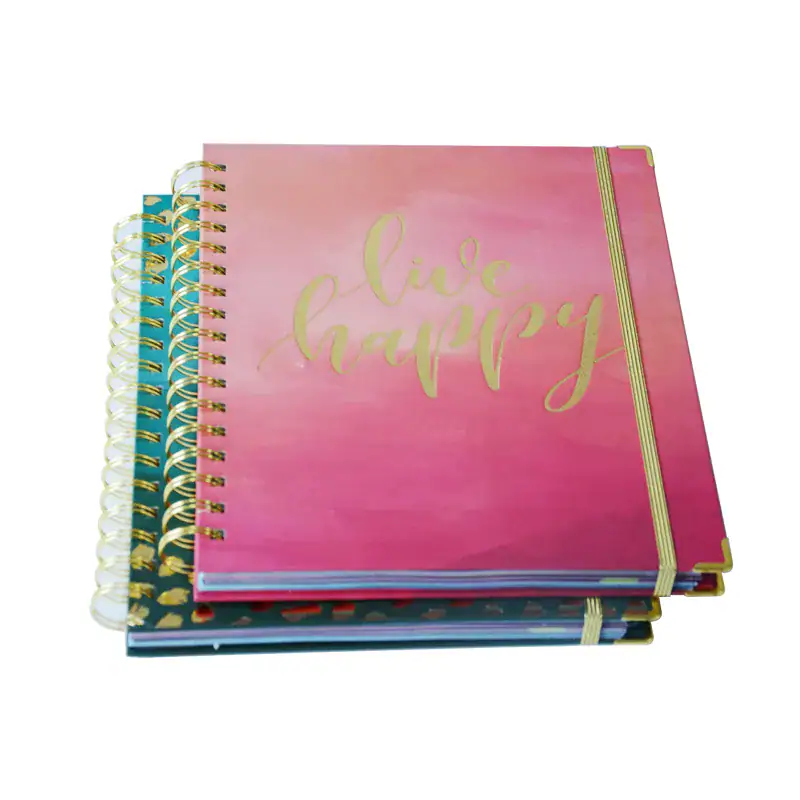

This case study takes you behind the scenes of a high-stakes custom notebook printing project. The client’s core creative feature—two exquisite “scratch-off gold” pages—was exceptionally fragile during production.

We will reveal how we implemented a “cost-agnostic,” nearly obsessive quality control system to transform a potential delivery disaster into an ultimate expression of perfection. It’s a story that proves a true partner dares to share the risk of bringing your vision to life.

Here’s a quick overview of the core challenge, our unique solution, and the final outcome of this complex project, helping you grasp the key takeaways at a glance.

Project at a Glance: The Epiphany Journal

The Client’s Vision

European design studio Atelier Lumina aimed to launch a flagship product, The Epiphany Journal, featuring a unique and highly fragile scratch-off gold foil interactive experience.

The Business Challenge

The delicate scratch-off foil faced a potential 20-30% spoilage rate during production, risking catastrophic cost overruns and severe damage to the client’s brand reputation.

Our Solution

We implemented a ‘Three-Tier Forensic-Level Protection Protocol,’ which included 100% manual inspection of every special sheet and multiple reprints at our own cost to ensure perfection.

The Final Outcome

A flawless batch of 2,500 notebooks was delivered, enabling a successful product launch for the client and solidifying our role as a trusted partner for high-risk, creative projects.

Meet the Client

In late 2024, Aria Chen, the Founder and Creative Director of the emerging European design studio Atelier Lumina, approached us. They were preparing a flagship product for their Spring/Summer 2025 collection: The Epiphany Journal.

This was no ordinary notebook; it was an interactive tool designed to spark creative inspiration, serving as their entry into the premium stationery market. The soul of its design lay in two unique scratch-off gold foil pages, which, when scratched, revealed beautifully designed motivational messages.

The Challenge

Aria’s vision quickly encountered a harsh reality. The scratch-off gold application, especially over a large surface area, is a notorious “yield killer” in the printing industry.

Its physical properties make it exceptionally fragile: any minor friction during production—from the stacking of paper to a worker’s touch—could leave a permanent scratch. The mechanical pressure of the binding process was a direct threat to its integrity.

The risks were quantifiable and severe:

- Extremely High Spoilage Rate: Initial tests indicated that even with the most careful handling, the spoilage rate for the special pages could reach 20-30% before the complex smyth-sewn binding stage even began.

- An Avalanche of Cost Overruns: To fulfill the order of 2,500 finished books, we would have to produce and pay for materials for hundreds of extra interior pages. Worse, if a defect was only discovered after the book was fully bound, the entire unit would be a loss.

- A Gamble on Brand Reputation: For Atelier Lumina, the biggest risk wasn’t financial. As a flagship product, any out-of-the-box defect would directly damage their carefully cultivated brand image and could sabotage their entire market launch.

Our Solution

Faced with a problem that threatened to derail the project, our team chose not to simply “inform the client of the risks and suggest a compromise.” We took the harder path: we decided to isolate the risk within our production facility and deliver perfection to the client.

We knew that standard random-sampling QC was completely inadequate. We had to create a new system, a quality control in book printing protocol built from the ground up specifically for this project. We called it our “Three-Tier Forensic-Level Protection Protocol”:

Tier 1 (Pre-Binding):

100% Manual Inspection to Build a “Perfection Pool.” Before any pages entered the binding phase, we instituted an unprecedented manual inspection process. Every single sheet—let me repeat, every single sheet—with the scratch-off gold foil was examined under high-intensity light by two QC specialists. Any page with the slightest scratch, impression, or blemish was immediately rejected. To gather enough “perfect” sheets for the full run, we reprinted these two core pages three separate times at our own cost.

Tier 2 (In-Process):

Re-engineering the Workflow to Minimize Contact. We analyzed every touchpoint that could create friction. We re-engineered the production line, from how the paper stacks were handled to adding shock absorption to transport carts, and retrained operators on new handling procedures. The singular goal: to reduce the probability of accidental contact with the gold foil to near zero.

Tier 3 (Pre-Shipment):

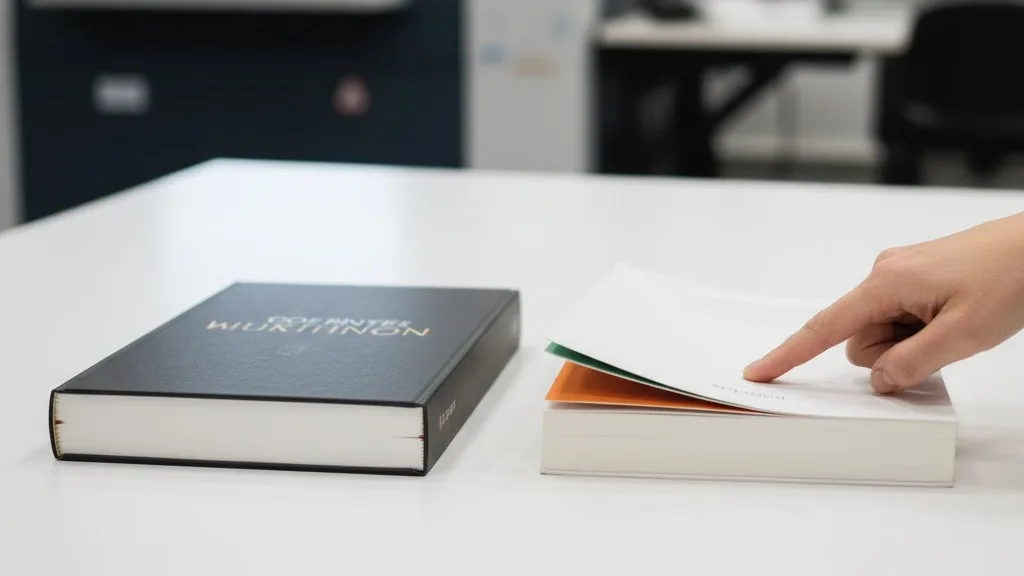

The Final Gauntlet to Lock in the Promise. As the final step before boxing, we conducted the last and most rigorous check. Our inspectors gently opened every single finished notebook, like one would a rare manuscript, to inspect the two critical gold pages one last time, ensuring they remained pristine after surviving the entire production journey.

Summary: The Three-Tier Protection Protocol

| Protection Tier | Key Action | Strategic Goal |

|---|---|---|

| Tier 1: Pre-Binding | 100% Manual Inspection | Create “Perfection Pool” |

| Tier 2: In-Process | Re-engineer Workflow | Minimize Contact Risk |

| Tier 3: Pre-Shipment | Final Unit-by-Unit Check | Guarantee Zero Defects |

This process was undeniably painful, involving higher labor costs and material waste that pushed the project into a financial loss for us. But we knew we weren’t just handling book printing errors; we were safeguarding the future of an emerging design brand.

The Results

When the final shipment arrived at Atelier Lumina’s studio in Europe, Aria Chen unboxed it herself. The cover had a refined tactile feel, and as she opened it, the two golden pages gleamed under the light with a complete, uniform, and flawless finish. She spot-checked dozens of copies, and each one perfectly replicated the intended experience.

Aria Chen later wrote to us in an email:

“We were uncompromising on The Epiphany Journal, because that ‘scratch-off’ moment is our entire brand promise. You not only understood that; you built a process to protect it that went beyond our expectations. What we received wasn’t 2,500 notebooks; it was 2,500 flawless brand experiences.”

In the end, we didn’t just deliver a shipment of high-quality notebooks to Atelier Lumina; we delivered certainty. We provided the rock-solid promise of quality that they could rely on, even in the face of extreme production uncertainty.

Bring Your Custom Notebook Vision to Life.

From unique materials to delicate special finishes like the scratch-off foil in this case study, we specialize in managing complex projects. Our experts ensure every detail is perfected, turning your most ambitious ideas into tangible, high-quality notebooks.

Project Specifications

| Attribute | Details |

|---|---|

| Project Name | The Epiphany Journal |

| Client | Atelier Lumina (European Design Studio) |

| Quantity | 2,500 copies |

| Dimensions | 150mm x 210mm |

| Cover | 2.5mm high-density greyboard, wrapped in Serenity™ Series deep navy linen-textured paper with gold foil stamping |

| Interior | 192 pages of 120gsm FSC-certified uncoated paper; includes two special inserts on 200gsm coated art paper |

| Core Process | Custom Scratch-Off Gold Foil application on special inserts |

| Binding | Smyth-sewn case binding |

Core Takeaway

For any creative project that strives for excellence, the greatest danger isn’t the cost; it’s the loss of control. A tiny flaw can undermine a grand vision.

This case study reveals our core value proposition: we are more than a printing service provider; we are professional risk managers for your creative vision.

We are willing to invest our expertise, our process design, and even our own profit to absorb the risks you face in realizing complex ideas, ensuring your final product is presented to the world exactly as you imagined it.

Do you have an exciting but complex printing project in mind? Are you looking for a partner who not only understands your creative intent but can also anticipate and neutralize risks?

Don’t let “technical difficulty” define the boundaries of your creativity.

Contact our team of experts today, and let’s discuss how we can build an unbreakable shield of quality around your most valuable ideas.

Ready to Demand Perfection for Your Project?

You’ve created the vision. Now let our experts handle the printing with the quality your project deserves.

References & Notes

[1] ‘Yield Killer’ in Printing: This is an industry term for a production process or material characteristic that inherently causes a high rate of product rejection (low yield). Processes involving delicate foils, complex die-cuts, or unstable materials are common examples.

[2] Smyth-sewn Binding & Production Risk: As a premium binding method, Smyth sewing involves collating signatures (groups of pages) and stitching them together before casing in. This requires multiple handling, folding, and transport stages, each presenting an additional risk of abrasion or damage to delicate surface finishes like scratch-off foils.

[3] Spoilage Rate for Special Finishes: The estimated 20-30% spoilage rate is a projection based on the multiple production touchpoints for a single sheet: printing, curing, stacking, transport to the binding line, and collation. Each step carries a cumulative risk of friction-based damage, which is significantly higher than for standard printed pages.