Confused by high book proofing costs? This guide provides a step-by-step breakdown of why a single sample is expensive and shows you how to manage your printing costs like a pro. Learn the insider strategies that protect your investment and ensure a perfect final product.

A single book proof is expensive because it absorbs the entire one-time fixed cost of a print job, including printing plates and press setup. In a bulk order, these same setup costs are distributed across many units, which significantly lowers the per-item price.

But understanding the ‘why’ is only the first step. In this guide, you’ll also discover the critical difference between digital and offset proofs, a checklist to catch costly errors, and the one question you must ask your printer before you approve anything.

The Core Analogy: Mass-Produced vs. Concept Cars

Think of it like the difference between a mass-produced car and a single, custom-built concept car.

Mass production is cheap because the factory’s massive setup cost is divided across thousands of units. The concept car, however, is incredibly expensive because it must absorb that entire setup cost alone. Your single book proof is the ‘concept car’ in this process.

Fixed vs. Variable Costs

In any production process, costs are broken into two categories:

- Fixed Costs: These are one-time setup expenses required to begin a job. They do not change whether you produce 1 item or 10,000 items. In offset printing, this includes making printing plates, creating custom dies for special finishes like foil stamping or embossing, and the significant time required to calibrate the press, all of which are key factors that impact book printing prices.

- Variable Costs: These are the costs of raw materials and per-unit labor that scale with the quantity of your order. This includes the paper, ink, and binding materials for each individual book.

When you order a bulk run of 1,000 books, the large fixed costs are divided by 1,000, becoming almost negligible on a per-unit basis. The price of each book is therefore dominated by its variable costs. A single proof, however, has no other units to share the burden. It must bear the entire weight of the fixed costs alone.

Visualizing the Cost Breakdown

To make this tangible, let’s look at a detailed, side-by-side cost comparison for a hypothetical book project.

| Cost Item | For 1 Proof (Absorbs All Fixed Costs) | For 1,000 Books (Fixed Costs are Shared) |

| Offset Printing Plates (CMYK) | $40.00 | $40.00 / 1000 = $0.04 |

| Foil Stamping Die (for cover) | $25.00 | $25.00 / 1000 = $0.025 |

| Press Setup & Calibration Labor | $30.00 | $30.00 / 1000 = $0.03 |

| International Air Express Shipping | $20.00 | (Uses sea freight; minimal cost per unit) |

| Subtotal: Fixed Costs Per Copy | $115.00 | ~$0.10 |

| Variable Costs Per Copy (Paper, Ink, Binding) | ~$5.00 | ~$4.90 |

| Final Price Per Copy (Example) | ~$120.00 | ~$5.00 |

Not an $80 Book, but a $5,000 Insurance Policy

Now that the logic behind the cost is clear, the next question is one of value. Is this high-priced sample truly worth it? To answer this, we must reframe what you are actually purchasing.

You are not buying an $80 book. You are investing in an $80 insurance policy for a project potentially worth $5,000 or more.

The physical proof, or “proof copy,” is your final and most critical opportunity to prevent a costly, large-scale, and irreversible error before you commit your capital to the full print run. It transforms the abstract—your digital files on a screen—into a tangible object you can hold, feel, and inspect.

The Only Opportunity to Avert Catastrophic Risk

Every year, countless creators and businesses face preventable losses because they chose to skip this crucial step.

We once worked with a promising wellness brand launching their first packaged product. To accelerate their timeline and save on initial costs, they approved the project based on digital files alone. When their 5,000 custom boxes arrived, they discovered that a key ingredient listed on the back panel had a typo.

This small error made their packaging non-compliant with labeling regulations, rendering the entire shipment unusable. An $80 proof would have allowed a dozen people on their team to review the physical box, almost certainly catching the error and saving them a five-figure loss.

Consider the primary risks that a physical proof almost single-handedly mitigates:

- Risk 1: The Color Tragedy: The vibrant, energetic red you perfected on your backlit computer monitor can easily print as a flat, lifeless maroon on paper. Screen colors (RGB) and print colors (CMYK) are fundamentally different, as Adobe explains in their guide to color models, and a physical proof is the only way to see how your design truly translates to ink on paper.

- Risk 2: The Permanent Typo: Your brain becomes adept at ignoring errors in a manuscript you’ve read a hundred times on screen. Holding a physical copy forces your brain to process the information differently. It’s often in this final, tactile review that a misspelled name on the spine or a glaring grammatical error in an introduction is finally caught.

- Risk 3: The Tactile Mismatch: You chose a 120gsm uncoated paper stock because it sounded premium. But when you hold the final product, it feels thinner and less substantial than you envisioned, cheapening the entire project. The proof is your only chance to physically experience the paper weight, the texture of a matte or gloss laminate on the cover, and the overall build quality.

As renowned book production consultant Joanna Penn often states, “The purpose of a proof is to find mistakes.” It is a tool for quality control. Viewing it as an optional expense rather than an integral part of the production process is a significant financial risk.

Offset vs. Digital Proofs and Making the Right Choice

Understanding the high cost of a setup-intensive offset proof leads to the next critical, more technical question: “How is my proof actually made, and is it different from the final run?” This is an excellent question, and the answer reveals how the professional printing industry has evolved to provide solutions that balance cost, speed, and accuracy.

To solve the high-cost problem of a true “press proof,” the industry offers two primary types of physical proofs. Knowing the difference empowers you to make the right choice for your project, a decision we explore further in our definitive comparison of offset vs digital printing.

Option A: The Offset Press Proof — The Perfect, but Costly, Original

- The Analogy: The “high-speed train.”

- Process and Cost: This is the ‘concept car’ we discussed earlier. It is a perfect, 100% accurate copy made on the exact same massive offset printing press, with the same custom-mixed inks and freshly made printing plates as your final bulk order. It requires the full, expensive setup detailed in the cost table, which is why it is not the standard offering.

- Application and Recommendation: This is a premium, specialized service. It is the right choice only when absolute, mission-critical color accuracy is non-negotiable. This applies to projects like high-end architectural lookbooks or projects that require specialized art book printing, where subtle tones are paramount, or materials for a global brand like Coca-Cola or Tiffany & Co., which have legally protected brand colors that must be matched perfectly.

Option B: The Premium Digital Proof — The Industry-Standard Solution

- The Analogy: The “agile supercar.”

- Process and Advantages: This is the industry-standard solution and almost certainly what you receive for your standard proofing fee. It’s printed on a high-end, industrial-grade digital press (like an HP Indigo press), which is a marvel of engineering that requires no plates or extensive setup. It can produce a single, high-quality copy directly from a digital file quickly and cost-effectively.

- Why It’s Recommended: The digital proof is the industry’s direct answer to the prohibitively high cost of an offset proof. It represents the optimal balance of cost, speed, and quality. It is designed to be about 95% accurate to the final offset-printed product, which is more than sufficient for verifying the most critical elements:

- Final text, layout, and image clarity.

- The true feel and finish of your chosen paper and cover materials.

- The quality and durability of the binding and construction.

- The primary difference lies in the imaging technology (digital presses often use a form of toner or electro-ink, while offset uses wet ink), which can result in very subtle variations in color gamut. For the vast majority of projects, this fractional difference is negligible and far outweighed by the immense cost and time savings.

Decision Matrix: A Clear Comparison

| Feature | Digital Proof (Industry Standard) | Offset Press Proof (Premium Service) |

| Color Accuracy | ~95% (Excellent for general representation) | 100% (An exact match of the final run) |

| Cost | Standard Fee (e.g., $80) | High (Typically $200 – $500+) |

| Turnaround Time | Fast (1-3 business days) | Slower (Requires full press scheduling) |

| Primary Purpose | Overall quality control: layout, materials, feel, binding | Mission-critical, exact color matching |

| Best For | Nearly all authors, startups, and creators | Fine art books, major corporate brands, color-specific packaging |

“Can I Request a Full Offset Press Proof?”

Yes, absolutely. We, and most professional printers, offer this as a premium service. If your project demands it and your budget accommodates it, you can request a true “press check,” where you might even be present at the facility to approve the colors as they come off the press.

However, for the vast majority of creators, the standard digital proof provides the essential insurance you need in a much more efficient and cost-effective package.

How to Inspect Your Proof

Once your proof arrives, the quality control process is in your hands. This is your final opportunity to give feedback before the presses run. It deserves your focused, undivided attention. Don’t just give it a quick glance; inspect it like a professional.

Your Ultimate Proof-Checking Checklist

Set aside time to review your proof in a well-lit area, preferably with natural daylight to get the truest sense of color. Use this comprehensive checklist to guide your review:

- [ ] Text and Layout: Read every single word. This is your last chance to catch typos, grammatical errors, or awkward phrasing. Check that page numbers are correct and sequential. Ensure chapter headings, subheadings, and paragraph styles are consistent. Look for any strange line breaks or spacing issues.

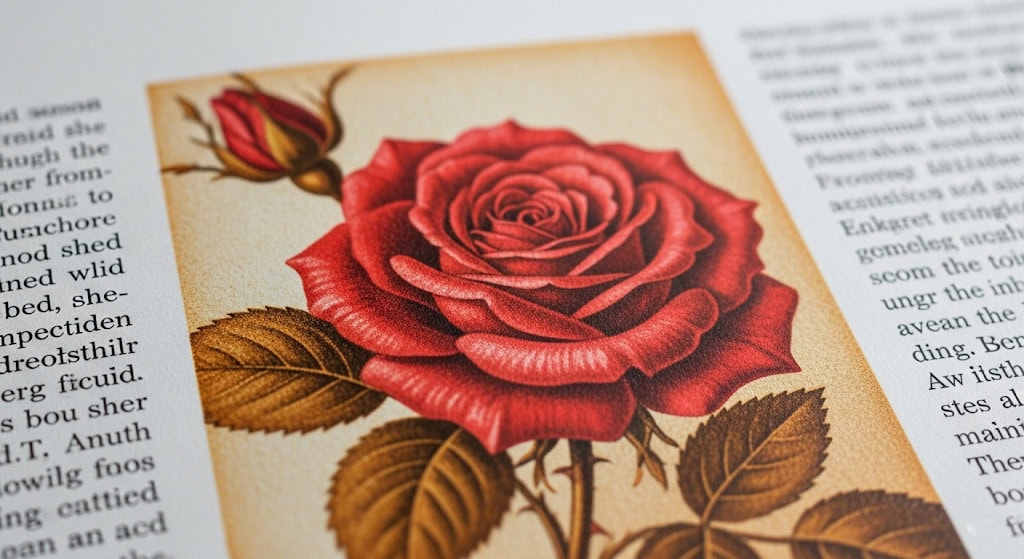

- [ ] Imagery and Graphics: Examine every photo and illustration. Are they sharp and clear, or do they look blurry or pixelated? Is their placement correct? Check the crop and margins around each image. For the cover, pay close attention to the alignment of all graphic elements.

- [ ] Paper and Feel: This is a purely tactile check. How does the paper feel between your fingers? Does the paper weight feel substantial and professional? Is the cover finish (e.g., gloss, matte, soft-touch laminate) what you expected? Hold a page up to the light—is it too transparent? The feel of the book is a huge part of the reader’s experience.

- [ ] Dimensions and Binding: Take out a ruler and measure the final trim size. Is it correct? Open and close the book several times. Fan the pages. Does the binding feel secure and durable? For perfect-bound books, check that the glue is neat. For hardcover books, check the hinge and endpapers.

- [ ] Special Finishes: If your project includes extras like foil stamping, embossing, debossing, or spot UV, inspect them closely. Is the foil application crisp and clean? Is the embossing aligned perfectly with the printed graphic beneath it? Run your fingers over it to check the depth and texture.

After you have thoroughly checked every point on this list, you are ready to communicate with your printing partner. You will either give your final, confident approval for production to begin, or you will provide clear, specific, and consolidated feedback for any necessary revisions.

Conclusion

You began with a valid question about printing costs and are now equipped with the knowledge to proceed with the confidence of a publisher.

Understanding the critical role of a book proof is a foundational element of that success. As your strategic production partner, we are committed to helping you realize your creative vision with transparency and quality through our expert book printing services.

Ready to take the next step? Contact our team of print specialists for a transparent quote and a no-obligation expert consultation.