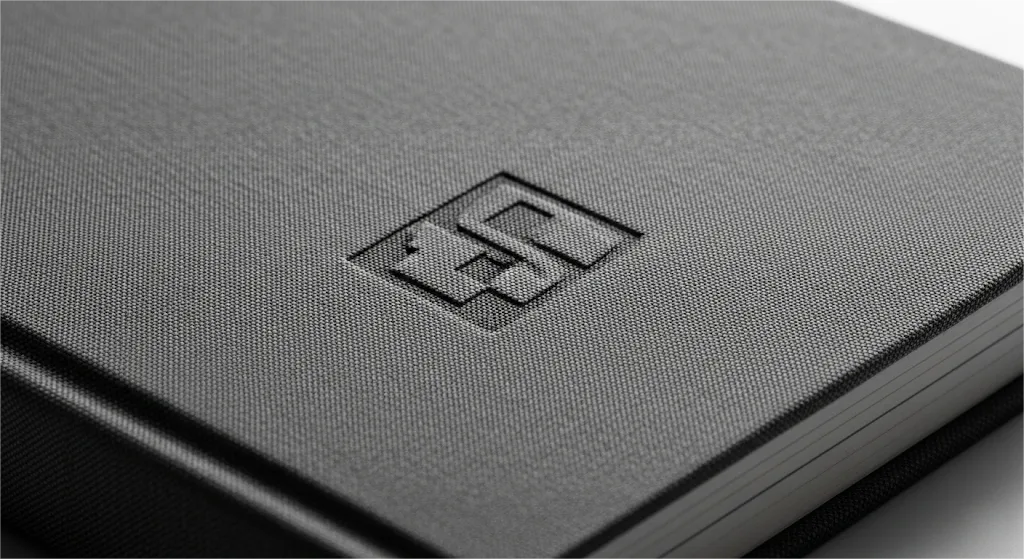

For high-end publishers, a refined debossed logo is the finishing touch that elevates a book’s perceived value. But when the canvas shifts from paper to cloth, a difficult challenge emerges: how to choose the right book cover material for debossing. The wrong material can turn a design that should be crisp and clean into a blurry, indistinct mess.

The key lies in the cloth’s weave density and surface smoothness. A texture that is too coarse will “swallow” the pressure from the debossing die, blurring the design’s edges. This is the most common cause of failure in cloth hardcover debossing.

Clear communication using standardized printing & finishing terms is the first step in avoiding such issues. This case study will show you how a professional printing partner transformed a near-failure into a textbook success through rigorous testing.

Project Impact at a Glance

Client

Form & Structure Press, a renowned European design publisher with exacting standards for brand detail.

Challenge

To achieve a clean, elegant debossed logo on a cloth cover for their flagship art book, Metropolis Ascendant, matching their high-end brand positioning.

Mainland Solution

Leveraging expert material science knowledge and conducting multiple rounds of proactive, complimentary testing to prove the limitations of the client’s initially specified material, ultimately providing the optimal material and process combination to perfectly realize their visual concept.

Results

Successfully averted brand damage and project delays from an incorrect material choice, ensuring the final product was 100% aligned with the client’s high-quality standards. This project initiated a long-term strategic partnership.

A Test of Brand Detail

Form & Structure Press, the renowned European design publisher, is famous for its meticulous attention to detail. While preparing for their key Autumn 2025 release schedule, they planned to launch their book of the year: a hardcover art book on contemporary architectural photography, titled Metropolis Ascendant: The New Face of Urban Architecture.

Positioned as their flagship project to enter the high-end architectural book market, the design’s core feature was a clean, sharp logo debossed onto a dark grey cloth cover. For any publisher, protecting a brand logo as an industrial design is a critical step in asset management.

The challenge arose when the client, during the quoting stage, specified a particular cloth model—”Arkwright Linen B-7″—recommended by their European supplier. However, our project manager knew from experience that this material’s coarse texture posed a high risk for fine, detailed debossing.

This created a dilemma: proceeding with the client’s request would almost certainly result in a failed sample that couldn’t meet their high standards. Yet, rejecting their choice outright could seem disrespectful.

The stakes were clear: the success of this single sample would determine whether we could win the trust of this exceptionally quality-conscious client.

From Passive Execution to Proactive Testing

We chose to win this test with facts and service that went beyond expectations.

Our team elevated a simple proofing job into a rigorous “material science experiment.”

Step 1: Respect the Client and Run the Test

First, we followed the client’s instructions precisely, creating a debossed sample using their specified “Arkwright Linen B-7.” As expected, the logo’s edges were blurry and lacked a premium feel.

But we didn’t stop there. We proactively tested two “remedial” processes, including adding a clear foil stamp over the deboss and comparing blind debossing vs foil stamping. Still, due to the fundamental flaws of the base material, the results remained subpar.

Step 2: Provide Additional Professional Samples at No Cost

After presenting all the failed samples from the first round, we offered our professional recommendation: “The material you specified has a texture that is too coarse to achieve the refined effect you’re looking for. We recommend using ‘FineLuxe 3-Series’ cloth, which has a much finer weave and is the ideal choice for crisp debossing.”

To prove our point, we made a crucial decision: we would produce an entire second set of samples using our recommended material at no cost to the client. We also included comparisons of various custom book finishes, allowing them to see and feel the dramatic difference between the materials firsthand.

Step 3: Empower the Client’s Decision

Finally, we shipped two large packages containing a total of six different sample variations to their Production Director, Elara Vance. We included a simple analysis report that clearly explained the pros and cons of each material and process.

We didn’t rush them. Instead, we handed over the complete evidence and our expert recommendation, empowering her to make the most informed decision.

At a Glance: Comparing the Two Approaches

| Factor | Client’s Initial Approach (High Risk) | Mainland’s Proactive Solution (Optimal Result) |

|---|---|---|

| Material | Coarse Weave (“Arkwright Linen B-7”) | Fine Weave (“FineLuxe 3-Series”) |

| Process | Passive Execution (Single Sample) | Proactive Testing (Multiple Free Samples) |

| Debossing Result | Blurry, Indistinct Edges | Sharp, Crisp, Premium Finish |

| Business Outcome | Project Risk & Brand Damage | Flawless Execution & Partnership |

A Partnership Won by Expertise

“Your team’s proactivity and technical expertise were the deciding factors. Other printers simply said ‘no,’ but Mainland demonstrated why the initial material was flawed and, more importantly, how to achieve a superior result. We’re proceeding with your recommended material and process.”

— Elara Vance, Production Director at Form & Structure Press

This was the direct quote from Elara’s email after receiving and comparing the two sets of samples. The final product perfectly realized their original design vision—the logo was sharp, the texture was refined, and the overall feel was one of premium quality.

This successful collaboration not only produced a flagship hardcover book for them but, more importantly, it showed them that Mainland is more than a factory that executes orders.

We are an expert partner who can anticipate challenges, proactively solve problems, and provide deep material consulting.

Since then, Form & Structure Press has entrusted all of their hardcover projects to us.

Project Specifications

| Category | Specification |

|---|---|

| Project Type | Hardcover Art Book |

| Dimensions | 241 x 305 mm (9.5″ x 12″) |

| Cover Material | “FineLuxe 3-Series” Charcoal Grey cloth over 1500gsm high-density greyboard |

| Cover Finish | Debossing |

| Interior Paper | 170gsm FSC-Certified Matte Art Paper |

| Print Run | 3,500 copies |

The Key Takeaway for You

The Key Takeaway: For projects that demand high-quality detail, the value of a printing partner lies not just in execution, but in their proactive material science knowledge and a professional ethos of proactive problem-solving.

A responsible partner will help you mitigate risks through expert testing to find the optimal path to realizing your creative vision, as discussed in this guide to special printing techniques.

Ensure Your Vision is Printed Flawlessly

From complex debossing to perfect paper choices, our experts are ready to turn your creative details into a beautiful, tangible book. Let’s get it right, together.

References & Notes

[1] Debossing vs. Embossing: Debossing creates an indented impression on a material by pressing a metal die down into its surface. This is the opposite of embossing, which creates a raised impression by pushing the material up from below. Debossing is often favored for its subtle, sophisticated tactile effect on materials like cloth and thick paper stock.

[2] Blind Debossing: The term “blind” refers to a debossing process that does not use any ink or foil. The impression’s visibility relies solely on shadow and texture, creating a minimalist and high-end aesthetic. This contrasts with foil stamping, where a layer of metallic or pigmented foil is applied to the surface using heat and pressure.

[3] FSC (Forest Stewardship Council) Certification: This certification ensures that the paper used in a project comes from responsibly managed forests that provide environmental, social, and economic benefits. For publishers and brands, using FSC-certified paper is a key indicator of a commitment to sustainability and ethical sourcing. Adhering to recognized book cloth and paper standards is crucial for quality and sustainability.