Considering special finishes like die-cuts or foil stamping for your next children’s book? This guide provides a practical, step-by-step playbook for independent publishers to navigate costs, avoid common production mistakes, and select the perfect designs to make your book stand out. We provide the expert insights you need to make smart investments that deliver real results.

Special finishes for children’s books are post-press processes like foil stamping, die-cutting, embossing, and Spot UV that add tactile and visual elements. Key considerations include the finish’s market impact versus its cost, correct production file setup, and strict adherence to child safety standards like CPSIA.

The full guide below breaks down the exact cost percentages for each finish and shares real-world case studies—including a costly $50,000 printing mistake and how you can avoid it.

Part 1: Strategy, Trends, and Inspiration

Investing in special finishes is a strategic decision. It’s about understanding what the modern market values and knowing the creative tools available to meet those demands.

Market Trends and Creative Possibilities

The children’s book market is currently experiencing two significant trends. First, there’s a clear shift away from gimmicks toward purposeful interaction. Today’s parents often seek calmer, more intentional products.

Second, sustainability has become a new form of luxury. Highlighting the use of FSC-certified papers or soy-based inks on your copyright page is a powerful selling point for an increasingly eco-conscious audience.

With these trends in mind, here is a toolkit of effective finishes categorized by the experience they deliver:

To Invite Touch (Sensory Finishes): Tactile engagement is fundamental to early childhood development. As neuroscientist Dr. Maryanne Wolf notes, the “sensorimotor information from holding and manipulating a book helps the brain to anchor and remember the content.”

- Flocking: A soft, fuzzy texture perfect for animals or blankets.

- Embossing/Debossing: Raised or indented patterns that add a three-dimensional feel to titles or illustrations.

To Create Surprise (Interactive Elements):

- Lift-the-Flap: A classic tool for reveals that builds anticipation. Ensure sturdy construction for repeated use.

- Die-Cutting: Custom-cut shapes that can create windows to peek at the next page or shape the entire book.

- Pop-Ups: From simple V-folds to complex structures, pop-ups provide the ultimate “wow” factor.

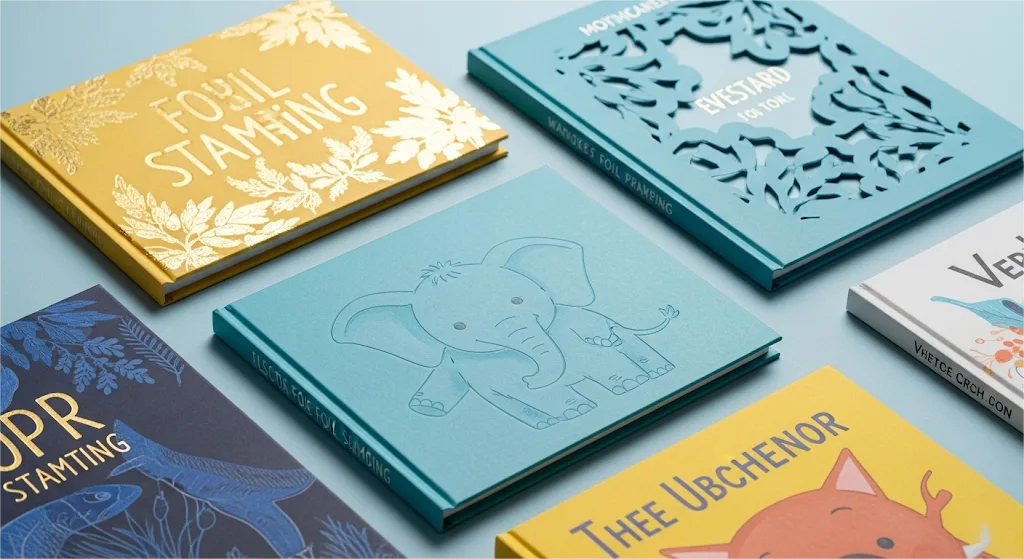

To Dazzle the Eye (Visual Finishes):

- Spot UV: A high-gloss coating applied to specific areas of a matte page, creating a subtle, sophisticated contrast.

- Foil Stamping: Using metallic or colored foils to add a touch of magic or luxury to titles and illustrations.

The key to a high-quality flap is durable construction and binding, ensuring it can withstand repeated use by enthusiastic little hands.

Why Design is Strategy

For some creators, interaction isn’t an add-on; it’s the core of the narrative.

Hervé Tullet, author of the groundbreaking book Press Here, reframed what an interactive book could be. He explained his philosophy simply: “I don’t make books for children, I make books for them to play with… The book is a game, a performance.”

This perspective encourages you to think about special finishes from the very beginning. When design and story are developed together, the result is an integrated, unforgettable experience.

Part 2: Decoding the Costs: A Publisher’s Guide to Budgeting and ROI

Let’s address the conversation that underpins every production decision: the budget. Investing in special finishes requires a clear understanding of the costs involved, not just as expenses, but as strategic investments in your product’s appeal and marketability.

The Cost vs. Impact Matrix

Special Finishes for Children’s Books: A Quick Reference Guide

| Special Finish | Primary Use & Effect | Relative Cost / Impact |

|---|---|---|

| Spot UV | Adds a high-gloss, reflective layer to specific areas of a matte cover, creating a subtle, premium visual contrast. | Low Cost / High Impact (Adds ~5-10% to unit cost) |

| Embossing / Debossing | Creates a raised (emboss) or indented (deboss) 3D texture, ideal for titles or adding a tactile element to illustrations. | Low Cost / High Impact Adds ~5-8% to unit cost) |

| Die-Cutting | Cuts custom shapes or “windows” into pages, creating peek-a-boo effects or uniquely shaped books. | Medium Cost / Medium Impact (Adds ~8-15% per page) |

| Lift-the-Flap | A classic interactive element for “reveal” moments that builds curiosity. Requires durable construction for longevity. | Medium Cost / Medium Impact (Adds ~15-25% per page) |

| Foil Stamping | Applies metallic or colored foil using heat and pressure, adding a sense of luxury, magic, or importance. | High Cost / High Impact (Adds ~15-30% to unit cost) |

| Flocking | Applies soft, fibrous particles to create a velvety, fur-like texture for a memorable sensory experience. | High Cost / High Impact (Adds ~20-40% per page) |

| Pop-Ups | Creates 3D structures that rise from the page, providing the highest level of interactivity and “wow” factor. | High Cost / High Impact (Can add 50%+ to unit cost) |

To simplify your decision-making, you can categorize options using a Cost vs. Impact matrix. This helps you identify where to allocate your resources for the greatest return.

- Low Cost, High Impact: Excellent starting points for a tight budget. Examples: Custom Debossing on Cover (adds ~5-8% to unit cost), Spot UV on a Matte Cover (adds ~5-10%).

- Medium Cost, Medium Impact: Proven interactive elements. Examples: Simple Die-Cuts (adds ~8-15% per page), Standard Lift-the-Flaps (adds ~15-25% per page).

- High Cost, High Impact: The showstoppers, best reserved for titles with strong commercial potential. Examples: Foil Stamping (adds ~15-30%), Flocking (adds ~20-40%), Complex Pop-Ups (can add 50%+).

(Note: percentages are estimates and vary based on complexity and quantity. All die-based processes also have a one-time tooling fee.)

Understanding Your Total Cost of Ownership

The low unit price on a quote is not the full story, as there are many key factors that impact book printing prices. You must consider the Total Cost of Ownership to avoid budget overruns.

A past client, “Sarah,” learned this the hard way. She chose a factory based on a very low unit price but was later hit with unexpected shipping fees and customs duties. Production delays caused her to miss the holiday sales window, and a portion of the books arrived with quality defects.

Her “cheap” book became a costly lesson, highlighting one of the most critical printing mistakes to avoid. To protect your investment, evaluate quotes using this formula:

Total Cost = (Unit Price x Qty) + Tooling Fees + Shipping + Tariffs & Duties + Cost of Time & Risk

Sample Budget Strategies

Your budget determines your strategy. For a smaller budget project (e.g., $5,000 for 2,000 board books), the smartest investment is often a high-impact cover, such as one with an elegant debossed title.

For a larger budget (e.g., $15,000 for 3,500 hardcovers), you can incorporate more interior complexity, such as a cover with Spot UV plus several interior lift-the-flaps.

Part 3: From File to Finished Book: A Guide to a Flawless Production Run

Meticulous attention to detail during the production stage is what separates a smooth, successful project from a stressful, costly one.

The Pre-Press Checklist

A perfect book begins with a perfect, print-ready file. Before submission, ensure your files meet these technical standards:

- Color Mode: All art is converted to CMYK.

- Resolution: All images are at least 300 DPI at their final print size.

- Bleed & Safety: A 3mm bleed is added to all edges, and important elements are within a 5mm safety margin.

- Fonts: All fonts are embedded or converted to outlines.

- Special Finishes: Die-cut lines, Spot UV areas, etc., are on separate, clearly labeled layers.

The Crucial Role of Prototyping

For any interactive book, there is one non-negotiable step: approving a physical “white sample” or “dummy.” This is a non-printed, fully assembled mock-up used to test the book’s structure and engineering.

Years ago, a client skipped this step on a $50,000 pop-up book order to save a week. The final books arrived with a structural flaw in the pop-up mechanism, rendering the entire shipment unsellable.

This was a painful but valuable lesson: always approve the engineering before you approve the color. The white sample is your insurance against structural failure. It allows you to test if flaps lift properly and pop-ups deploy smoothly before you commit to the full print run.

Safety and Compliance Standards

For children’s products, quality control is synonymous with safety. Your manufacturing partner must be able to confirm compliance with international standards, as outlined in this definitive guide to children’s book printing safety, to protect both children and your business.

- For the US Market: This means adherence to CPSIA (Consumer Product Safety Improvement Act), which sets strict limits on lead and phthalates and includes testing for small parts that could be choking hazards.

- For the EU Market: This requires CE Marking, signifying conformity with the EN 71 toy safety directive.

- Physical Safety: All books for young children should be designed with rounded corners and durable construction to prevent injuries.

Part 4: Finding Your Partner, Not Just a Printer

The success of your book depends on the partner you choose. You need a collaborator who understands your vision and can help you navigate the complexities of production.

Key Questions for Your Potential Manufacturer

When vetting a partner, ask these critical questions:

- Is your hand-assembly done in-house or outsourced? (In-house offers better quality control.)

- Can you walk me through your mandatory white sample process? (Their enthusiasm for this step reveals their professionalism.)

- Are you fully compliant with CPSIA/CE standards? (This is non-negotiable.)

- Who will be my dedicated point of contact? (Clear communication is essential.)

- Can you provide a DDP (Delivered Duty Paid) quote to my final warehouse? (This ensures cost transparency.)

Conclusion: Your Next Masterpiece Awaits

Creating a children’s book with stunning special finishes and designs is a detailed process, but it is a manageable one. By balancing your creative vision with a strategic budget and partnering with an experienced manufacturer, you can produce a book that stands out for all the right reasons.

If you are ready to explore the possibilities for your next title, we invite you to a free, no-obligation Project Feasibility & Creative Consultation. Let’s discuss your vision and build your next success story, together.